-

Kelengkapan Pipa Titanium

-

Pipa Dilas Titanium

-

Flensa Pipa Titanium

-

Tabung Titanium Mulus

-

Penukar Panas Titanium

-

tabung koil titanium

-

Lembar Paduan Titanium

-

Pengencang Titanium

-

Kawat Las Titanium

-

Batang Bulat Titanium

-

Tempa Titanium

-

Tembaga Berbalut Titanium

-

Elektroda Titanium

-

Target Sputtering Logam

-

Produk Zirkonium

-

Filter Berpori Sinter

-

Bentuk Memory Nitinol Wire

-

Produk Niobium

-

Produk Tungsten

-

Produk Molibdenum

-

Produk Tantalum

-

Produk Peralatan

-

produk aluminium

-

Produk baja tahan karat

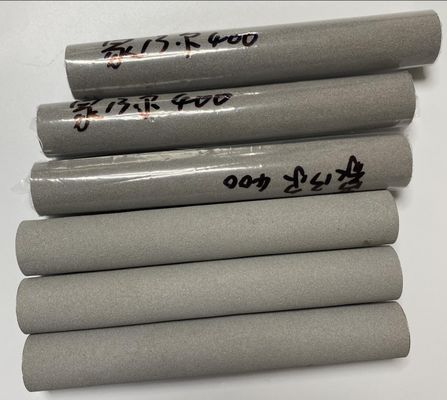

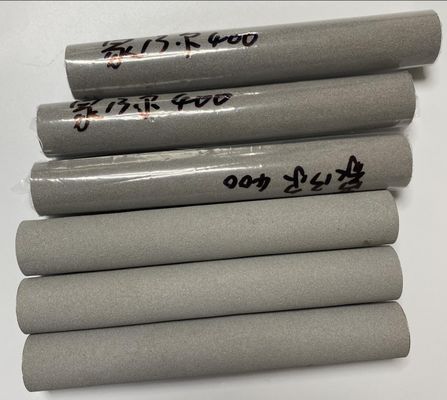

Porous Sintered Metal Filter Tube SS 316L For Catalyst Recovery Chemical

| Tempat asal | CINA |

|---|---|

| Nama merek | CSTY |

| Sertifikasi | ISO 9001;2015 |

| Nomor model | SS316L |

| Kuantitas min Order | 5-10pcs |

| Harga | USD56/pc |

| Kemasan rincian | film dan kotak kayu, Kemasan karton bisa sesuai dengan kebutuhan pelanggan. |

| Waktu pengiriman | 10-15 hari |

| Syarat-syarat pembayaran | L/C, T/T, Western Union, Moneygram, Paypal |

| Menyediakan kemampuan | 200 pcs/bulan |

Hubungi saya untuk sampel gratis dan kupon.

ada apa:0086 18588475571

Wechat wechat: 0086 18588475571

Skype: sales10@aixton.com

Jika Anda memiliki masalah, kami menyediakan bantuan online 24 jam.

x| Resistensi abrasi | Tinggi | Resistensi suhu | ≤400℃ |

|---|---|---|---|

| Layanan Sampel | Memberikan sampel untuk pengujian | Tekanan maksimal | 2.0Mpa |

| Bahan | SS 316L, Titanium, Inconel600, Monel400, Etxc. | layanan lainnya | Platium, Ir, Ru melapisi pelat titanium |

| Perawatan permukaan | Pemolesan | Area penyaringan | 0,3-1,0m2 |

| Keuntungan | porositas dan permeabilitas tinggi | Jenis | elemen filter titanium |

| Kekuatan tekan | ≥0.6mpa | Peringkat filter | 0.5um-50um |

| Memfilter media | bubuk nikel | Kehidupan kerja | Lebih dari 10 tahun |

| Suhu | 0-200 ℃ | ||

| Menyoroti | tabung filter logam sinter SS 316L,Filter logam berpori untuk pemulihan katalis,Filter berlubang sinter untuk bahan kimia |

||

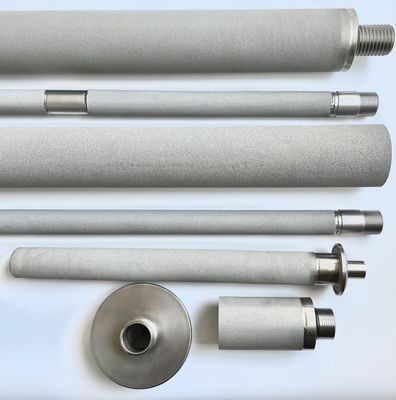

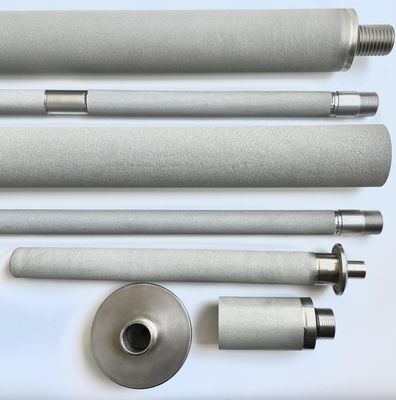

Introduction

Compared with traditional filtration materials such as paper, cotton, PP, PE, PES, and PTFE, metal powder sintered porous materials offer superior performance.

They feature excellent permeability, uniform pore size and pore control, stable shape, high filtration accuracy, wear resistance, and outstanding mechanical strength.

Additionally, these materials exhibit good heat conduction, heat resistance, and dissipation performance, allowing them to be washed and reused multiple times without significant loss of performance.

Specifications

| Product Name | SS 316L Sintered Tube |

|---|---|

| Material | Pure Titanium / SS316L / Bronze |

| Size | OD 20–80 mm × WT 2.5–3.0 mm × L 10–1200 mm |

| Filter Accuracy | 0.5–80 µm |

| Connection | Customized according to customer requirements |

| Applications | Sparging, Separation and Filtration, Carbonation, Liquid Filtration, etc. |

Technical Parameters

| Filter Accuracy (µm) | Porosity (%) | Permeability (m³/m²·h·kPa) | Compression Strength (MPa) | Temperature Tolerance (°C) | Max Working Pressure (MPa) |

|---|---|---|---|---|---|

| 0.5–50 | 20–50 | 3–800 | 2–3 | 250 | 0.6 |

Performance Features

Excellent mechanical strength and structural stability

Uniform pore size distribution and good air permeability

Superior chemical stability and corrosion resistance

High temperature resistance (up to 250 °C)

Acid and alkali resistance

Fireproof, anti-static, and reusable

Long service life with consistent filtration efficiency

Application Environments

Suitable for use in environments containing:

Nitric acid, sulfuric acid, acetic acid, oxalic acid, phosphoric acid, 5% hydrochloric acid, molten sodium, liquid hydrogen, liquid nitrogen, hydrogen sulfide, acetylene, water vapor, hydrogen gas, coal gas, carbon dioxide gas, and other chemically aggressive media.

Widely used in:

Catalyst recovery and chemical processing

Beverage and food production

Metallurgy and refining

Coarse and fine liquid filtration

Dust and oil mist removal from gases and vapors

Sound attenuation, flame retardancy, and gas buffering applications