-

Kelengkapan Pipa Titanium

-

Pipa Dilas Titanium

-

Flensa Pipa Titanium

-

Tabung Titanium Mulus

-

Penukar Panas Titanium

-

tabung koil titanium

-

Lembar Paduan Titanium

-

Pengencang Titanium

-

Kawat Las Titanium

-

Batang Bulat Titanium

-

Tempa Titanium

-

Tembaga Berbalut Titanium

-

Elektroda Titanium

-

Target Sputtering Logam

-

Produk Zirkonium

-

Filter Berpori Sinter

-

Bentuk Memory Nitinol Wire

-

Produk Niobium

-

Produk Tungsten

-

Produk Molibdenum

-

Produk Tantalum

-

Produk Peralatan

-

produk aluminium

-

Produk baja tahan karat

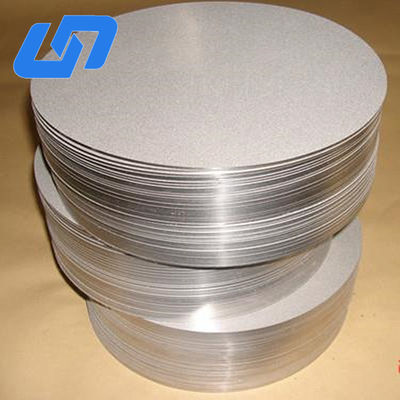

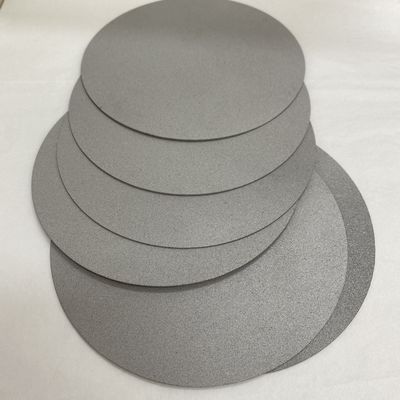

Sintered Plate Inconel600 Titanium SS 316L For Filtration And Separation

| Tempat asal | CINA |

|---|---|

| Nama merek | CSTY |

| Sertifikasi | GB/T19001-2016/ISO9001:2015 |

| Nomor model | SS316L |

| Kuantitas min Order | 10kg |

| Harga | $80.00 - $110.00/ Piece |

| Kemasan rincian | film dan kotak kayu, Kemasan karton bisa sesuai dengan kebutuhan pelanggan. |

| Waktu pengiriman | 15 ~ 20 hari kerja |

| Syarat-syarat pembayaran | L/C, T/T, Western Union, Moneygram, Paypal |

| Menyediakan kemampuan | 5000 Kilogram/Kilogram per Bulan |

Hubungi saya untuk sampel gratis dan kupon.

ada apa:0086 18588475571

Wechat wechat: 0086 18588475571

Skype: sales10@aixton.com

Jika Anda memiliki masalah, kami menyediakan bantuan online 24 jam.

x| Akurasi filtrasi | 0.1um | Resistensi abrasi | Tinggi |

|---|---|---|---|

| ciri | Digunakan di lingkungan yang sangat korosif | Area penyaringan | 0,3-1,0m2 |

| Spesifikasi | 0,5um, 2um, 5um, 10um, | Diameter | 50-1000mm |

| Bahan | Titanium, SS 316L, Inconel600, dll. | Layanan Sampel | Memberikan sampel untuk pengujian |

| Jenis | Disk Logam, SS Filter | Standar | ISO9000 |

| Tekanan kerja | 2-3Mpa | Sedang mengemas | Paket Ekspor Standar |

| Kehidupan Layanan | 2-5 Tahun | Tekanan maksimal | 2.0Mpa |

| dimensi | Disesuaikan | ||

| Menyoroti | Sinter pelat filter Inconel600 berlubang,Plat penyaring titanium yang disinter,SS 316L pelat pemisah sinter |

||

Introduction

Compared with traditional filtration materials such as paper, cotton, PP, PE, PES, and PTFE, metal powder sintered porous materials offer superior performance. They provide excellent permeability, precise pore size control, stable shape, high filtration accuracy, wear resistance, good mechanical strength, and excellent heat conduction and dissipation.

Moreover, sintered metal materials can withstand high temperatures, maintain their shape under stress, and be cleaned and reused multiple times, making them a durable and cost-effective filtration solution.

Specifications

| Product Name | Sintered Plate |

|---|---|

| Material | Pure Titanium / SS316L / Bronze / Inconel 600 |

| Size | OD 20–80 mm × WT 2.5–3.0 mm × L 10–1200 mm |

| Filter Accuracy | 0.5–80 µm |

| Connection | Customized according to customer requirements |

| Applications | Sparging, Separation and Filtration, Carbonation, Liquid Filtration, etc. |

Technical Parameters

| Filter Accuracy (µm) | Porosity (%) | Permeability (m³/m²·h·kPa) | Compression Strength (MPa) | Temperature Tolerance (°C) | Max Working Pressure (MPa) |

|---|---|---|---|---|---|

| 0.5–50 | 20–50 | 3–800 | 2–3 | 250 | 0.6 |

Applications

The sintered plate is widely used in industries including electronics, water treatment, food and beverage, biotechnology, chemicals, petrochemicals, metallurgy, and gas purification. It represents a new generation of filtration materials with broad development potential.

Typical applications include:

-

Sparging

-

Separation and Filtration

-

Carbonation

-

Liquid Filtration

-

Catalyst Recovery

-

Steam Filtration

-

Slurry Oil Filtration

-

Flame Arrestors

-

Sound Silencing

-

Fluid Distribution and Control

-

Semiconductor Manufacturing

-

Fuel Cell Stacks

-

Coating Electrodes

-

Damping and Shock Absorption

-

Heat Exchange

-

Bio-Implants

Properties

-

Uniform pore size and stable pore structure with high separation efficiency

-

High porosity, low filtration resistance, and excellent permeability

-

Outstanding chemical stability and resistance to acids, alkalis, and oxidation

-

Morphological stability—no particle shedding; compliant with food hygiene and pharmaceutical GMP standards

-

Strong mechanical properties, low differential pressure, and large flow capacity

-

Excellent anti-microbial characteristics, non-reactive with microorganisms

-

Easy online regeneration, backwashing, and long service life

-

Excellent biocompatibility for use in biological, food, pharmaceutical, and medical applications

-

Effective electromagnetic shielding performance

-

Strong damping and shock resistance