-

Kelengkapan Pipa Titanium

-

Pipa Dilas Titanium

-

Flensa Pipa Titanium

-

Tabung Titanium Mulus

-

Penukar Panas Titanium

-

tabung koil titanium

-

Lembar Paduan Titanium

-

Pengencang Titanium

-

Kawat Las Titanium

-

Batang Bulat Titanium

-

Tempa Titanium

-

Tembaga Berbalut Titanium

-

Elektroda Titanium

-

Target Sputtering Logam

-

Produk Zirkonium

-

Filter Berpori Sinter

-

Bentuk Memory Nitinol Wire

-

Produk Niobium

-

Produk Tungsten

-

Produk Molibdenum

-

Produk Tantalum

-

Produk Peralatan

-

produk aluminium

-

Produk baja tahan karat

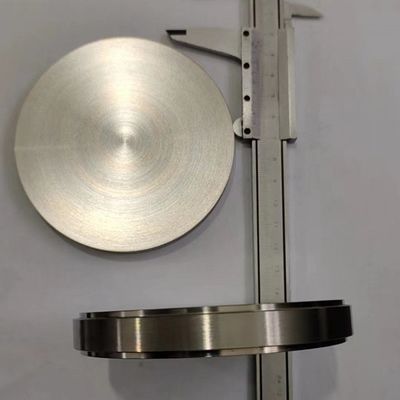

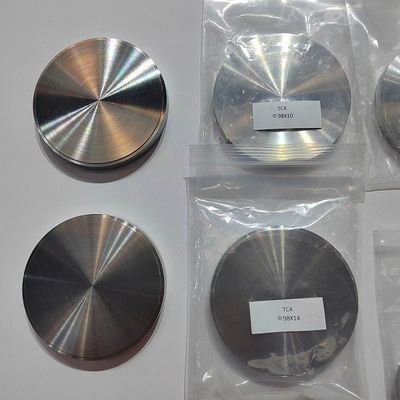

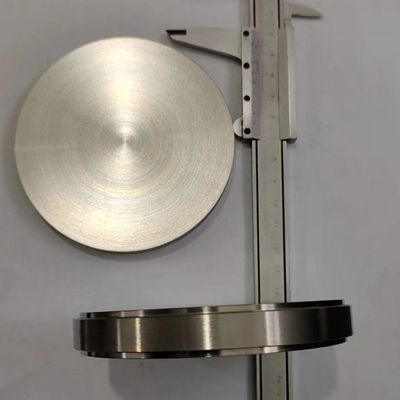

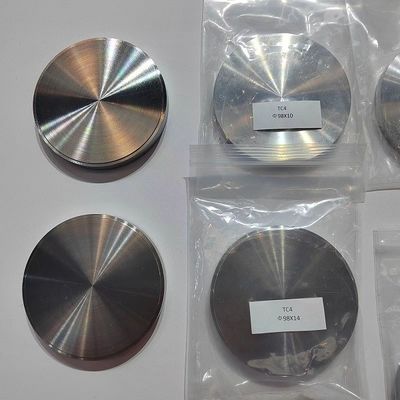

Sasaran Katode Metal Sputtering Custom dengan Konduktivitas Superior dan Ketebalan Seragam untuk Proses Lapisan Industri

| Place of Origin | China |

|---|---|

| Nama merek | Changsheng |

| Sertifikasi | ISO 9001;2015 |

| Model Number | ASTM F67,ASTM F136 ASTM B381 |

| Minimum Order Quantity | 200pcs |

| Harga | USD24/pc |

| Packaging Details | wooden case,carton Packaging can be according to customer requirements. |

| Delivery Time | 15~20 work days |

| Payment Terms | L/C, T/T, Western Union, MoneyGram,paypal |

| Supply Ability | 10000pcs/month |

| Menyoroti | sasaran katode penyemprotan logam khusus,sasaran penyemprotan logam konduktif,sasaran penyemprotan tebal seragam |

||

|---|---|---|---|

Deskripsi produk:

Target Metal Sputtering adalah komponen penting yang banyak digunakan dalam bidang teknologi deposisi film tipis, terutama dalam proses Physical Vapor Deposition (PVD).Sebagai target katode Metal Sputtering berkualitas tinggi, dirancang untuk memberikan kinerja dan keandalan yang luar biasa dalam berbagai aplikasi industri dan penelitian.Produk ini berfungsi sebagai bahan baku yang diatomisasi dan disimpan pada substrat untuk menciptakan seragam, lapisan logam kemurnian tinggi, membuatnya sangat diperlukan dalam pembuatan semikonduktor, lapisan optik, hiasan, dan elektronik canggih.

Dibuat dari logam kelas premium, Target Metal Sputtering memastikan kemurnian yang superior dan integritas struktural,yang sangat penting untuk mencapai tingkat penyemprotan yang konsisten dan kualitas film yang optimalSasaran ini dirancang untuk menahan kondisi yang ketat dari ruang penyemprotan, termasuk lingkungan vakum tinggi, pemboman plasma yang intens, dan suhu tinggi.Sifat-sifat ini membuatnya menjadi pilihan ideal untuk Deposisi Uap Fisik Tujuan aplikasi di mana daya tahan dan presisi adalah yang terpenting.

Salah satu fitur menonjol dari Metal Sputtering Cathode Target ini adalah fleksibilitasnya.memungkinkan untuk digunakan dengan berbagai peralatan dan prosesFleksibilitas ini memungkinkan produsen dan peneliti untuk menyesuaikan proses pelapisannya dengan persyaratan bahan dan ketebalan tertentu, yang pada akhirnya meningkatkan kinerja produk akhir.Apakah aplikasi membutuhkan lapisan konduktif tipis untuk mikroelektronik atau lapisan pelindung yang kuat untuk komponen industri, target penyemprotan ini memberikan hasil yang konsisten dan berkualitas tinggi.

Metal Coating Sputtering Target juga dibedakan dengan toleransi dimensi yang tepat dan permukaan akhir.Proses pemesinan dan polesan yang cermat digunakan untuk memastikan datar dan seragam, yang sangat penting untuk generasi plasma yang stabil dan erosi seragam selama penyemprotan.mengurangi waktu henti dan biaya operasional bagi penggunaSelain itu, desain target dapat disesuaikan untuk memenuhi persyaratan ukuran dan bentuk tertentu, mengakomodasi sistem sputtering yang unik dan memaksimalkan pemanfaatan bahan.

Dalam hal pilihan bahan, Metal Sputtering Target tersedia dalam berbagai jenis logam termasuk aluminium, tembaga, titanium, nikel, wolfram,dan logam mulia seperti emas dan platinumSetiap pilihan logam menawarkan sifat fisik dan kimia yang berbeda yang memenuhi kebutuhan aplikasi yang berbeda.target aluminium disukai untuk konduktivitas yang sangat baik dan reflektivitas, sementara target titanium memberikan ketahanan korosi dan kekuatan yang superior.Berbagai bahan ini memastikan bahwa pengguna dapat memilih target yang ideal untuk mengoptimalkan proses pelapisannya dan kinerja produk.

Selanjutnya, proses manufaktur dari Metal Sputtering Cathode Target menggabungkan teknik metalurgi canggih seperti peleburan vakum, pemalsuan panas, dan penggulungan panas,yang meningkatkan homogenitas target dan meminimalkan kotoranProses ini berkontribusi pada peningkatan efisiensi penyemprotan dan perekat film, yang sangat penting untuk pelapis berkinerja tinggi.termasuk analisis kimia dan pengujian non-destruktif, diterapkan secara ketat untuk menjamin bahwa setiap target memenuhi standar industri yang ketat.

Secara keseluruhan, Target Metal Sputtering adalah komponen penting untuk mencapai hasil pelapis yang unggul dalam proses Deposisi Uap Fisik.dan kompatibilitas dengan berbagai metode penyemprotan membuatnya menjadi alat yang sangat diperlukan untuk memproduksi film tipis yang andal dan berkualitas tinggiApakah digunakan sebagai Metal Sputtering Cathode Target dalam pembuatan semikonduktor atau sebagai Metal Coating Sputtering Target dalam dekoratif dan pelindung lapisan,produk ini secara konsisten memberikan kinerja yang sangat baik, daya tahan, dan nilai.

Memilih target metal sputtering yang tepat dapat secara signifikan mempengaruhi efisiensi dan kualitas proses sputtering.pengguna mendapat manfaat dari peningkatan keseragaman film, mengurangi kontaminasi, dan memperpanjang umur target. Hal ini akhirnya mengarah pada peningkatan hasil produksi, biaya pemeliharaan yang lebih rendah, dan karakteristik produk akhir yang lebih baik.Untuk industri yang menuntut presisi dan keunggulan dalam pelapis film tipis, Metal Sputtering Target menonjol sebagai solusi yang dapat diandalkan dan berkinerja tinggi.

Fitur:

- Target logam kemurnian tinggi yang memastikan kualitas pelapis yang unggul

- Dirancang sebagai Target Sumber Metallic Sputtering untuk deposit material yang efisien

- Keseragaman dan kepadatan yang sangat baik untuk kinerja penyemprotan yang konsisten

- Kompatibel dengan berbagai sistem sputtering dan aplikasi

- Sumber Metallic Sputtering yang tahan lama dan andal Sasaran untuk umur panjang

- Tersedia dalam berbagai komposisi logam untuk memenuhi berbagai kebutuhan industri

- Produksi presisi untuk memenuhi standar industri yang ketat

Parameter teknis:

| Nama produk | Target logam pencemaran sputter |

| Jenis | Sasaran logam penyemprotan vakum |

| Kemurnian | Target logam kemurnian tinggi (≥ 99,99%) |

| Bahan | Berbagai logam (misalnya, Al, Cu, Ti, Ni) |

| Dimensi | Ukuran khusus tersedia (misalnya, diameter 50-150 mm, ketebalan 1-10 mm) |

| Kepadatan | Dekat dengan kepadatan teoretis logam |

| Perbaikan permukaan | Permukaan halus yang dipoles untuk penyemprotan optimal |

| Aplikasi | Digunakan dalam proses deposisi sputter untuk pelapis film tipis |

| Kompatibilitas | Kompatibel dengan sebagian besar sistem penyemprotan vakum |

Aplikasi:

Changsheng Metal Sputtering Target, tersedia dalam model ASTM F67, ASTM F136, dan ASTM B381, adalah produk berkualitas tinggi yang dirancang untuk berbagai aplikasi industri canggih.Sebagai Sasaran Logam Berkualitas Tinggi, ia memainkan peran penting dalam proses deposisi film tipis, memastikan kinerja pelapis yang unggul dan konsistensi.produk ini menjamin keandalan dan keunggulan untuk penggunaan profesional.

Salah satu kesempatan aplikasi utama untuk Changsheng Metal Sputtering Target adalah dalam industri semikonduktor dan elektronik.Target Sputtering Metal Industri sangat penting untuk pembuatan perangkat mikroelektronik, sirkuit terintegrasi, dan transistor film tipis. kemurnian tinggi memastikan kontaminasi minimal, menghasilkan komponen elektronik berkinerja tinggi dengan daya tahan dan efisiensi yang ditingkatkan.Hal ini membuatnya ideal untuk digunakan di lingkungan kamar bersih di mana presisi dan kualitas adalah yang terpenting.

Selain elektronik, Target Deposisi Film Tipis ini banyak digunakan dalam produksi pelapis optik.dan komponen optik lainnya untuk meningkatkan transmisi cahaya, refleksi, dan daya tahan. target Changsheng sputtering memberikan komposisi unsur yang konsisten,yang sangat penting untuk mencapai film tipis seragam dengan adhesi yang sangat baik dan sifat optik.

Target Sputtering Logam Changsheng juga banyak digunakan di sektor otomotif dan aerospace untuk mendepositkan lapisan pelindung dan dekoratif pada berbagai bagian logam.Target kelas industri membantu meningkatkan ketahanan korosi, ketahanan terhadap keausan, dan daya tarik estetika, sehingga memperpanjang umur komponen penting dalam kondisi operasi yang sulit.000 pcs per bulan dan jumlah pesanan minimal 200 pcs, produk mendukung permintaan manufaktur skala besar secara efisien.

Bisnis mendapat manfaat dari syarat pembayaran yang fleksibel termasuk L/C, T/T, Western Union, MoneyGram, dan PayPal, membuat pengadaan lancar dan nyaman.Setiap pesanan dikemas dengan hati-hati dalam kotak kayu atau kartonWaktu pengiriman biasanya berkisar antara 15 hingga 20 hari kerja, memastikan pasokan tepat waktu untuk jadwal produksi yang sedang berlangsung.

Dengan harga yang kompetitif di USD 24 per keping, Changsheng Metal Sputtering Target menawarkan nilai yang sangat baik tanpa mengorbankan kualitas.dan kepatuhan terhadap standar kualitas internasional membuatnya menjadi bahan yang sangat diperlukan bagi organisasi yang terlibat dalam deposit film tipis dan teknologi pelapis canggih di seluruh dunia.

Dukungan dan Layanan:

Target Metal Sputtering kami dirancang untuk memberikan kinerja yang luar biasa dan keandalan dalam proses deposisi film tipis.Kami memberikan bantuan yang komprehensif termasuk panduan pemilihan bahan, pembuatan target khusus, dan saran pemecahan masalah untuk mengoptimalkan aplikasi penyemprotan Anda.

Kami menawarkan konsultasi ahli untuk membantu Anda memilih komposisi target yang tepat dan ukuran sesuai dengan kebutuhan spesifik Anda.Tim kami juga dapat membantu dengan prosedur pemasangan target dan tips pemeliharaan untuk memastikan umur maksimum dan kualitas film yang konsisten.

Selain produk standar, kami menyediakan layanan khusus seperti target paduan, target komposit, dan target dengan plat pendukung khusus atau bahan perekat.Proses kontrol kualitas kami menjamin bahwa setiap target memenuhi kemurnian yang ketat dan spesifikasi dimensi.

Untuk setiap pertanyaan teknis atau permintaan layanan terkait dengan Target Metal Sputtering kami,tim dukungan kami berkomitmen untuk memberikan solusi yang tepat waktu dan efektif untuk meningkatkan proses manufaktur Anda dan hasil produk.

Kemasan dan Pengiriman:

Kemasan dan Pengiriman Produk

Target penyemprotan logam kami dikemas dengan hati-hati untuk memastikan pengiriman yang aman dan menjaga integritas produk.Setiap target dibungkus dengan bahan pelindung untuk mencegah kerusakan permukaan dan kontaminasi selama transit.

Sasaran kemudian ditempatkan dalam kotak yang kokoh, dirancang khusus dengan bantalan yang memadai untuk menyerap kejut dan getaran.Desiccants dan kantong anti-statik digunakan untuk menjaga kualitas target dan mencegah oksidasi.

Kami menawarkan berbagai pilihan pengiriman untuk memenuhi kebutuhan pengiriman Anda, termasuk standar, dipercepat, dan layanan pengiriman barang.

Setelah menerima pesanan Anda, silakan periksa kemasan dan produk segera. Jika ada kerusakan, hubungi tim layanan pelanggan kami segera untuk bantuan.

FAQ:

T1: Merek dan nomor model apa yang tersedia untuk Target Metal Sputtering?

A1: Target Metal Sputtering ditawarkan di bawah merek Changsheng dan tersedia dalam nomor model ASTM F67, ASTM F136, dan ASTM B381.

T2: Sertifikasi apa yang dimiliki Target Metal Sputtering?

A2: Produk ini disertifikasi dengan ISO 9001:2015, memastikan standar manajemen mutu dipenuhi.

Q3: Berapa jumlah pesanan minimum dan harga per potongan?

A3: Jumlah pesanan minimum adalah 200 buah, dan harga adalah USD 24 per buah.

T4: Metode pembayaran apa yang diterima untuk membeli Target Metal Sputtering?

A4: Kami menerima pembayaran melalui L / C, T / T, Western Union, MoneyGram, dan PayPal untuk kenyamanan Anda.

Q5: Apa waktu pengiriman dan kemasan khas untuk Target Metal Sputtering?

A5: Waktu pengiriman biasanya 15 sampai 20 hari kerja. Pengemasan dilakukan dalam kasus kayu atau karton dan dapat disesuaikan sesuai dengan kebutuhan pelanggan.